Electrical system

For mobile

use the system is powered from a standard 80 Ah, 12V lead battery. This

is enough for playing 3-4 hours. The battery is placed under the feeder

crankshaft. This photo shows its immediate environment when the battery

is removed. Connections are concentrated to a clip-on contact bar, here

less a protective cover. The bar holds contacts for remote meters for

voltage and current, for an 'intelligent' battery charger, and for

accessories. Apart from the chest magnets these accessories

include the MIDI diskette reader and the master keyboard. These are

originally equipped with 220 VAC adaptors. At present they are powered

via an inverter from 12 VDC into that mains voltage, an obvious area

for future rationalization.

In the background of this photo you see the feeder drive motor with its

control box and its intermediate gear shaft. These are mounted on a

cradle, pivoting around rubber washers, one of them seen below the

contact bar. The belt connecting the intermediate shaft to the

crankshaft is tensioned by a spring, hardly visible below the

intermediate gear wheel.

|

|

The meters

for voltage and current are located up on the right pillar for easy

reading. Their ranges are modified to suit the application.

|

|

Motor drive regulator

In normal free standing use air is

supplied by the bellows, powered

from a battery driven motor. This motor is an old style 12VDC car

generator, slightly modified. The speed of this motor is controlled

such that the air reservoir lid is held at an intermediate position,

sensed by a linear potentiometer, R8 in this diagram.

A1 is an

oscillator, astable multivibrator. Its hysteresis is controlled by the

positive feedback network R1-3 and its frequency by R5-C1, with the

elements shown about 8 kHz. In A2 the sawtooth at C1 is compared to the

voltage of the bellows sensing potentiometer R8. This results in a

pulse width modulation signal at A2 output pin 1. I had to insert an

emitter follower Q1 for sufficiently fast drive to the power FET Q2.

When everything is turned on by switch S1 and relay S2, the slow

charging of capacitor C2 implements in a raw and simple way a smooth

acceleration of the motor, no overly big start current. I did

unsuccessfully try some ways to make an over current cutout by sensing

the drop over the fuse F. Skipped that after all, did not seem too

necessary. The fuse remains from earlier versions, but I doubt it is

very meaningful. |

|

I modified the car generator somewhat,

insulating its

second brush from the grounded case. Also swapped to connect that one

to the 'DF' terminal rather than the field winding, instead field was

connected to the case. The terminal denominations in the diagram are

after modification - the original generator was not internally

connected the way shown.

The pulse width modulation of the

supply to the rotor controls the average

voltage across it (between

D+ and DF) to be from essentially zero up to the battery voltage. This

voltage is about proportional to the motor speed, in turn connected to

airflow delivered. On the other hand the average current through the rotor

is in proportion to the torque delivered, and this torque is

essentially constant since pressure in the driven bellows is

independent of how much air is consumed. But this current is drawn from

the battery only at the open part of the duty cycle, when Q2 is turned

on. With Q2 off the same current flows in the rotor (due to the

inertial effect of its inductance) with a return path though the

'freewheel diode' D1. The result is that the average current and power

drawn from the battery is proportional to air usage, despite the fact

that motor current is constant.

This photo

shows my

endeavors to cram everything into a small metal box, riding piggyback

on the motor. It remains a bit awkward to me how to unite such

miniature

electronic circuits with the high current power ones, connected with

nuts and bolts rather than tiny solders. The power semiconductors D1

and Q2 are mounted on insulating washers inside the box, using the same

bolts as for the middle two external connections.

Q2 fused a couple of months after this photo. The replacement was

mounted on a big external heatsink seen in the top photo of this

section.

|

|

|

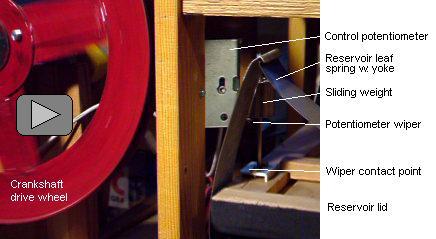

The

control potentiometer R8 is a linear one made for mixer consoles. I

connected its two 10 kohm stereo runs in parallel to have a 5 kohm pot

with possibly less noise. The picture shows the rig with the

reservoir bellows lid in empty position. In the lower half of the lid

travel

the pot arm is held in its bottom position (for full motor speed) by a

weight sliding on the vertical guide pin. The upper half of its travel

the lid pushes the pot up over a 60 mm range.

|

The 8 kHz magnetostriction whine from

the motor is faintly audible but

does not disturb the music. I prefer to keep it for a while, just as an

operator's check that everything works as it should. Later I might

reduce C1 to make it supersonic.

One feature of the connections layout is that if (or when?) the

electronics break down, then I can move the motor DF cable to the

adjacent B- terminal and let the motor go at full speed all the time.

Then it is up to the old

proven reservoir valve regulation to take over, though more noisy and

jerky.

Practically, this setup works fine. The battery consumption is about

13A, rising to some 17A when playing loud. Some power saving, but not

very significant. The assembly becomes a bit hot, some 65 deg C, at

continuous use. As far as I can judge the heat comes from the motor

rather than the electronics.

Using this speed regulation there is now much less rumble from the

bellows when the organ idles,

because of reduced speed, crankshaft only at about 20 rpm. Full speed

45 rpm

is reached momentarily at loud passages. This is a very pleasing

improvement, the one making the speed regulator adventure really

worthwhile.

Here

is a video recording (15 MB) seen from the opposite side. It shows how

the reservoir is rapidly filled when the motor is started. Since the

soundtrack has automatic gain control the background noises and bellows

squeaking are prominent. After a few seconds music starts vigorously

such that the reservoir lid dives, but the regulating system catches up

fast. It is difficult to perceive that the drive wheel speed varies a

lot.

|

|

|